1. The engineering plastic shell is made of glass fiber reinforced unsaturated polyester resin, which has excellent properties such as anti-static, impact resistance, corrosion resistance, and good thermal stability;

2. The stainless steel shell is welded with stainless steel plates, with a brushed surface that looks beautiful and elegant;

3. The aluminum shell is formed by aluminum alloy die-casting, and the surface powder is electrostatically sprayed;

4. The L series products are resistant to strong acids, strong alkalis, and salts, with a corrosion resistance level of WF1;

5. The G and S series products are more resistant to strong acids, alkalis, and salts, with a corrosion resistance level of WF2;

6.The L and S series products have a labyrinth sealing structure, while the G series products have a curved sealing structure. Both sealing structures have good waterproof and dustproof performance,

7. All exposed fasteners are made of stainless steel and sealed with silicone rubber, which is oil resistant, acid resistant, alkali resistant and anti-aging;

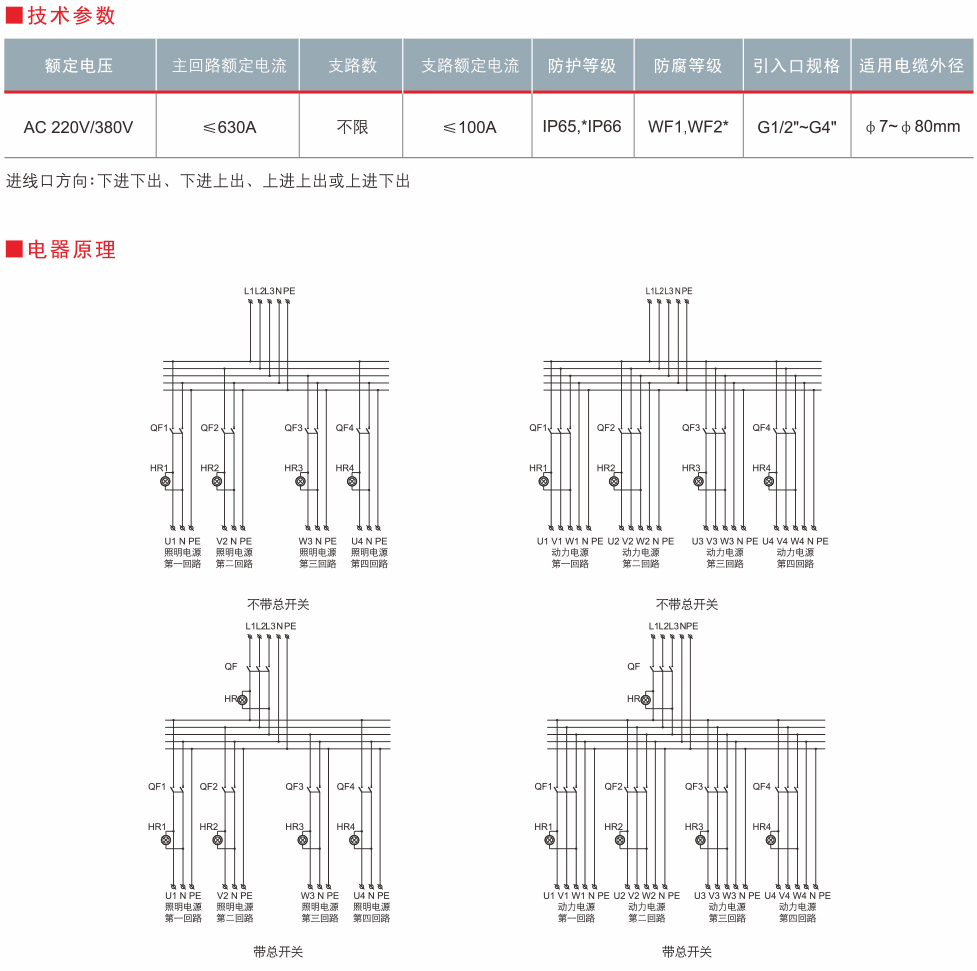

8. It is equipped with high breaking miniature circuit breakers or molded case circuit breakers, and can be opened and closed by simply opening the transparent waterproof window on the shell cover during operation;

9. It has overload and short circuit protection functions, and can produce products with leakage protection function according to user requirements;

10. It can be used for the distribution or switching of lighting circuits or power circuits, and can also be mixed for lighting, power distribution or switching;

11. This product generally uses cable wiring. If steel pipe wiring is required, please specify separately.