Features

1. Aluminum alloy die-casting shell, after high-speed shot peening, the surface is coated with high-voltage electrostatic spraying, which is corrosion resistant and anti-aging.

2. Stainless steel exposed fasteners have high anti-corrosion performance.

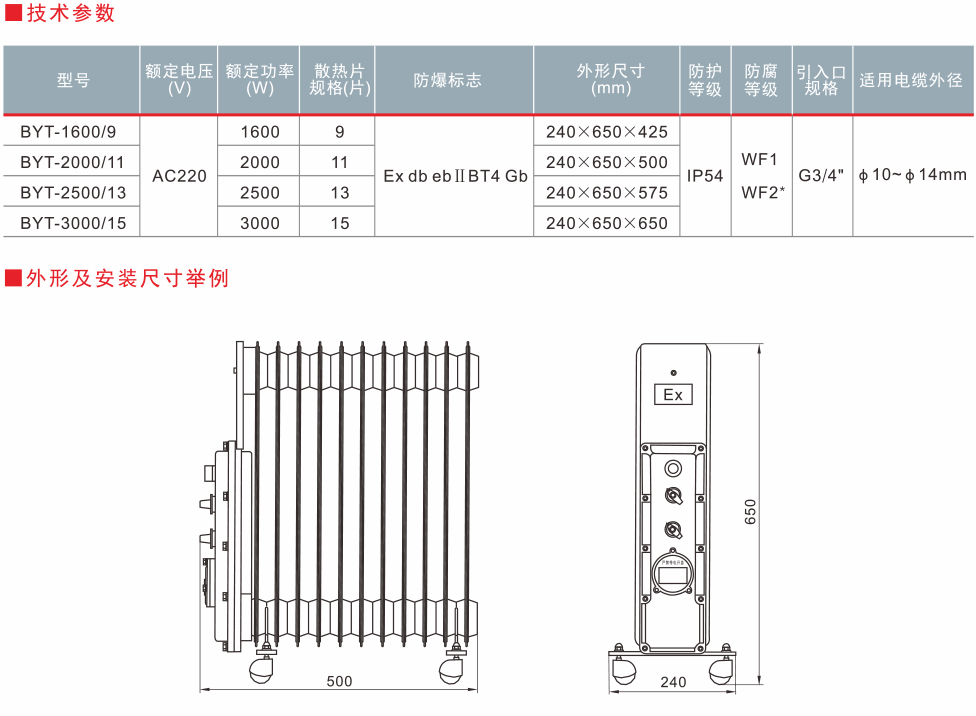

3. The product consists of three parts: heating element, explosion-proof junction box explosion-proof control box, and mobile foot.

4. The overall explosion-proof structure is a composite type composed of explosion-proof and increased safety types.

5. The heating element is composed of several oil sealed heat dissipation fins with built-in heaters. After heating, the thermal oil automatically circulates and alternates along the pipeline to form a stable heat source.

6. The explosion-proof junction box and explosion-proof control box are integrated as a whole. The junction box is an increased safety explosion-proof structure, and the power cord enters the junction box through a cable entry device and is connected to the terminal block. The explosion-proof control box is a flameproof structure, and the flat flameproof surface is connected to the heating element through bolt fastening to form a whole. The built-in electrical components include power regulators, temperature controllers, power indicator lights, etc. Grounding devices are installed inside and outside the junction box.

7. The mobile foot is composed of a bracket and universal casters, which are mechanically fixed to the oil tank to form a whole, allowing the oil tank to freely move and change direction on a relatively smooth floor or ground.

8. Cable wiring.